译者注:01-SDMS-01是所有SEC配网技术规范的基础,其中前面的01代表配网物资类别(如32代表环网柜),SDMS是SEC配网材料技术规范的缩写(SEC Distribution Material Specification),后面的01代表这个品类下的序号,一般会有几个细分的规范。而01-TMSS-01是输变电的技术规范的基础,不是配网的通用规范。一般这里配网指的是变电站之外的线路。

1. SCOPE 范围

This Specification describes the general requirements applicable to all the SEC Distribution Materials Specifications (SDMSs). Accordingly, all the SDMSs shall always be read in conjunction with this Specification.

本规范描述了适用于所有SEC配电材料规范(SDMS)的通用要求。因此,所有SDMS应始终与本规范一起阅读。

2. APPLICABLE CODES AND STANDARDS 适用的规范和标准

2.1 The tendered equipment/material shall fully conform to or exceed the minimum requirements stipulated herein and the SDMS for the said equipment/material.

2.1 投标的设备/材料应完全符合或超过本规范和所述设备/材料的SDMS中规定的最低要求。

2.2 Items not specifically covered herein and in the SDMS for the said equipment/material, shall be in accordance with the latest editions of referenced Industry codes and standards.

2.2 本规范和所述设备/材料的SDMS中未特别涵盖的项目,应符合最新版本的参考行业规范和标准。

2.3 It shall be the manufacturer's/vendor's responsibility to be or become knowledgeable of the requirements of the latest Industry codes and standards listed in the associated SDMS and bring to the attention of SEC, any latest revisions of the referenced Industry codes and standards which may have an impact on the technical requirements of the SDMS.

2.3 制造商/供应商有责任了解所列的最新行业规范和标准的要求,并在发现可能影响SDMS技术要求的最新修订时,通知SEC。

2.4 If the manufacturer/vendor uses equivalent codes and standards, he shall clearly mention the same in his bid proposal and obtain SEC approval before proceeding with manufacture. The equivalent codes and standards shall be equal to or better than those specified in the associated SDMS and the manufacturer shall have extensive experience in using these equivalent codes and standards. Copy of the equivalent codes and standards and the comparison with the specified codes and standards shall be provided to SEC for review and acceptance.

2.4 如果制造商/供应商使用等效的规范和标准,应在投标提案中明确提及,并在继续制造之前获得SEC的批准。等效的规范和标准应与所列SDMS中的要求相等或更好,且制造商应具有使用这些等效规范和标准的丰富经验。应向SEC提供等效规范和标准的副本,并进行与指定规范和标准的比较,以供审查和接受。

2.5 It shall be noted that SEC interpretation of this specification as well as the associated SDMS shall be binding on the manufacturer/vendor.

2.5 应注意,SEC对本规范以及相关SDMS的解释将对制造商/供应商具有约束力。

2.6 In case of any apparent conflict in requirements, the order of precedence shall be:

2.6 如果在要求中出现明显冲突,优先顺序应为:

2.6.1 SEC purchase order or contract schedules, as applicable.

2.6.1 SEC采购订单或合同进度表(如适用)。

2.6.2 SDMSs for the said equipment/material.

2.6.2 所述设备/材料的SDMS。

2.6.3 This specification.

2.6.3 本规范。

2.6.4 Other applicable Industry codes and standards.

2.6.4 其他适用的行业规范和标准。

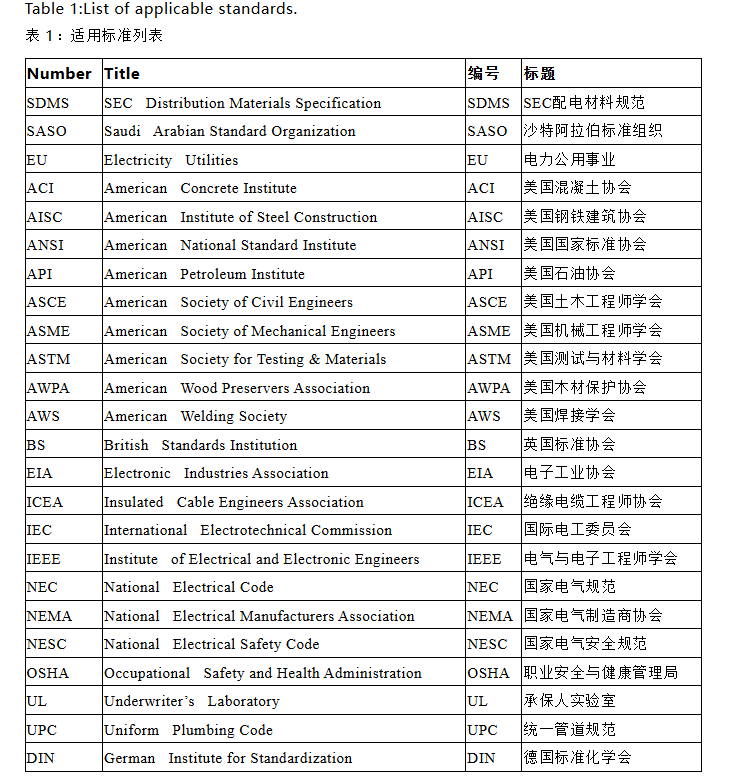

2.7 The following acronyms are used in the various SDMSs:

2.7 以下缩略语在各SDMS中使用:

The latest revision of the following codes and standards shall be applicable for the equipment/material covered in this SDMS. In case of conflict, the vendor/manufacturer may propose equipment/material conforming to one group of codes and standards quoted hereunder without jeopardizing the requirements of this SDMS.

以下规范和标准的最新修订版应适用于本SDMS中涵盖的设备/材料。如果出现冲突,供应商/制造商可以提出符合下列某一组规范和标准的设备/材料,而不影响本SDMS的要求。

3. SYSTEM PARAMETERS 系统参数

Unless otherwise specified in the associated SDMS, the equipment/material shall be suitable to operate under the typical system parameters tabulated, as applicable:

除非在相关SDMS中另有规定,否则设备/材料应适用于在下表所列的典型系统参数下运行,适用时使用:

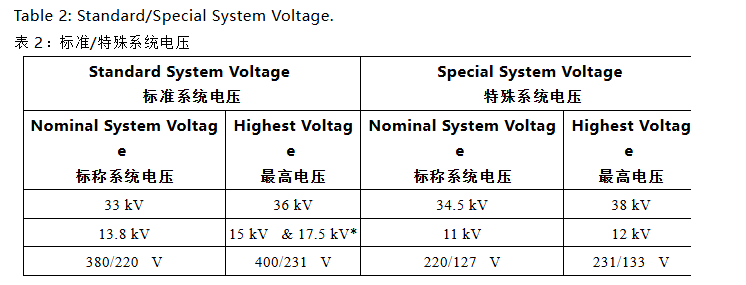

3.1 VOLTAGE 电压

The normal system Voltage and special system voltage shall be as tabulated below:

正常系统电压和特殊系统电压应如下表所示:

*All Switchgears shall be rated for 17.5kV.

*所有开关柜的额定电压均为17.5kV。

Note:The equipment shall be rated for the highest voltage values. Fault calculations and analysis shall be based on the highest voltages.

注意:设备额定电压应按最高电压值计算。故障计算和分析应基于最高电压。

3.2 FREQUENCY 频率

3.2.1 Standard frequency shall have a nominal value of 60Hz.

3.2.1标准频率应为60Hz的标称值。

3.2.2 All equipment's should be designed for system frequency of 60Hz.

3.2.2所有设备应设计为适应60Hz的系统频率。

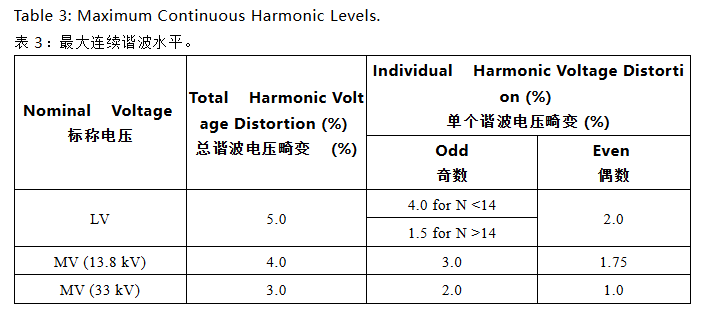

3.3 HARMONICS 谐波

The level of harmonics in the power system shall not exceed the values, as tabulated below, on a continuous basis.

电力系统中的谐波水平应持续不超过下表中列出的值。

Note: 注释

N: is the harmonic order, or multiple of the fundamental frequency.

N:是谐波阶数,或基频的倍数。

Voltage distortion is expressed as a percentage of the fundamental voltage.

电压畸变以基准电压的百分比表示。

The indicated values refer to maximum continuous levels.

所示的值指的是最大连续水平。

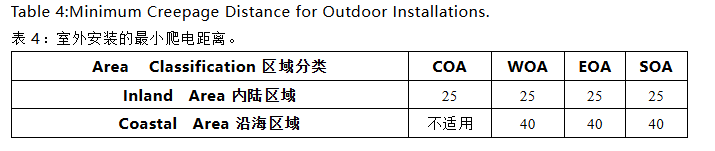

3.4 CREEPAGE DISTANCE 爬电距离

3.4.1 Outdoor Installations 户外安装

All outdoor bushings/insulators shall have a minimum creepage/leakage.

所有户外套管/绝缘子应具有最小的爬电/泄漏距离。

Note: 注释

Coastal Area is defined as the area located within a distance of 100 km from the coastline for EOA and 50 km for WOA & SOA. Whereas the area beyond these limits is defined as Inland Area.

沿海区域定义为位于距海岸线100公里以内的区域适用于EOA,50公里以内的区域适用于WOA和SOA。超过这些限制的区域定义为内陆区域。

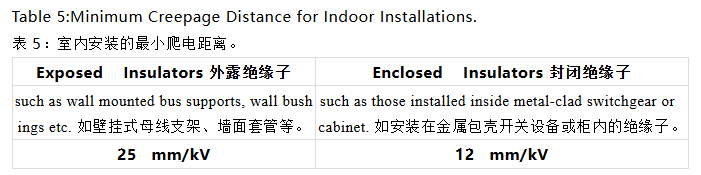

3.4.2 Indoor Installations 室内安装

The minimum creepage/leakage distance for indoor installations shall be as follows:

室内安装的最小爬电/泄漏距离应如下所示:

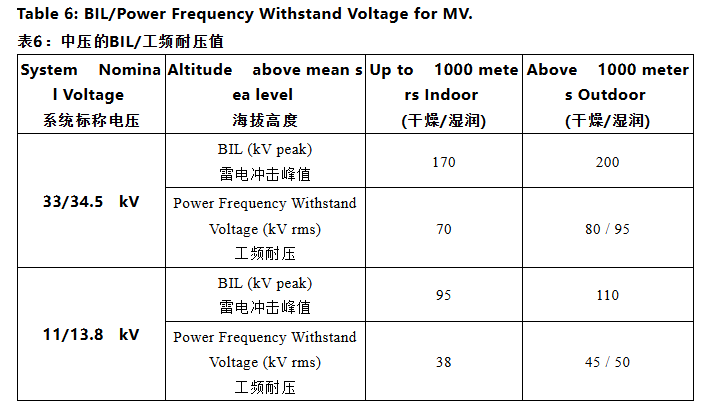

3.5 INSULATION LEVELS 绝缘等级

3.5.1 The basic insulation level (BIL) and power frequency withstand voltage for medium system voltages are as tabulated below.

3.5.1中压系统电压的基本绝缘水平(BIL)和工频耐压值如表所示。

Note: 注释

The dry/wet power frequency withstands voltages are for both shall be for one (1) minute.

干/湿工频耐压值应持续1分钟。

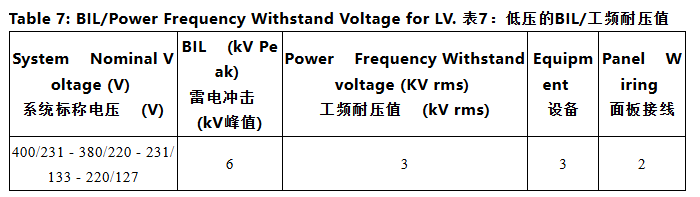

3.5.2 The basic insulation level (BIL) and power frequency withstand voltage for low system voltages are as tabulated below.

3.5.2低压系统电压的基本绝缘水平(BIL)和工频耐压值如表所示。

Notes: 注释

External insulation refers to the insulation of equipment exposed to the open air which will be influenced by atmospheric conditions, such as pollution and humidity.

外部绝缘指的是暴露在空气中的设备绝缘,这些设备将受大气条件的影响,如污染和湿度。

External insulation is further categorized into two categories:

外部绝缘进一步分为两类:

i. Outdoor insulation which is totally susceptible to atmospheric radiation, pollution, humidity, sandstorms, and such other vagaries of nature.

户外绝缘完全受大气辐射、污染、湿度、沙尘暴等自然变化的影响。

ii. Indoor insulation which is installed inside a building or outside a building but inside an enclosed box such as a cable box, terminal box, etc., where it is not directly subjected to outdoor atmospheric extremities.

室内绝缘是安装在建筑物内或建筑物外但在封闭盒子内,如电缆盒、接线盒等,在这些地方不会直接受到户外极端气候的影响。

ii. IPxx, protection index shall be as specified in the respective materials Specification.

ii. IPxx,保护等级应按照相应材料规范中规定的标准。

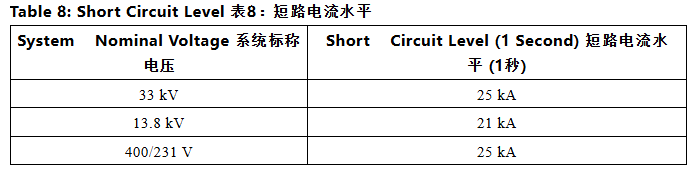

3.6 SHORT CIRCUIT LEVELS 短路电流水平

The minimum short circuit level for one second unless otherwise specified in the relevant SDMS shall be as follows:

除非在相关SDMS中另有规定,最小短路电流水平应为以下所示:

Note: 注释

For 13.8kV indoor metal-clad switchgear with SF6 or Vacuum C.B, short circuit shall be 25kA for 1 sec.

对于13.8kV室内金属封闭开关设备,使用SF6或真空断路器时,短路电流应为25kA,持续1秒。

3.7 NEUTRAL ARRANGEMENT 中性接地安排

Unless otherwise specified in the associated SDMS, the neutral shall be solidly grounded for system low voltages and solidly grounded or low resistance for system medium voltages.

除非在相关SDMS中另有规定,对于低压系统,中性点应采用牢固接地;对于中压系统,中性点应采用牢固接地或低电阻接地。

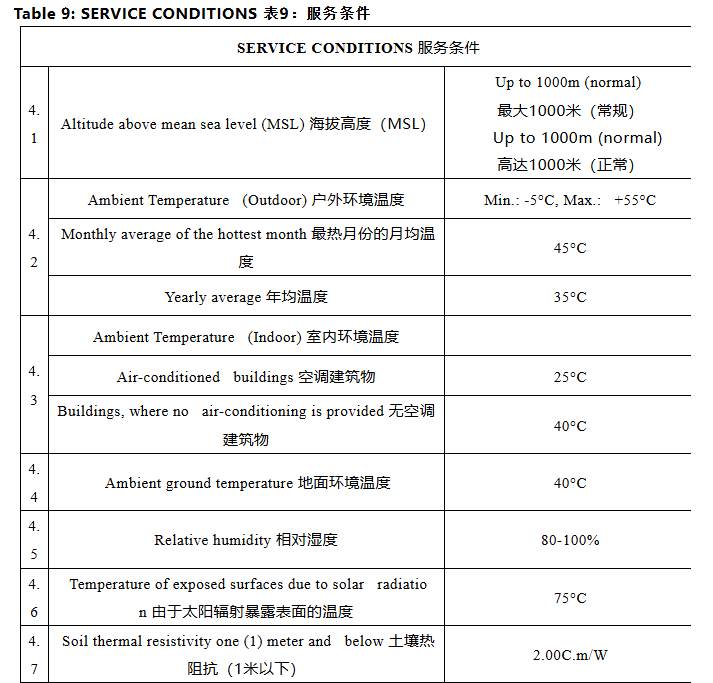

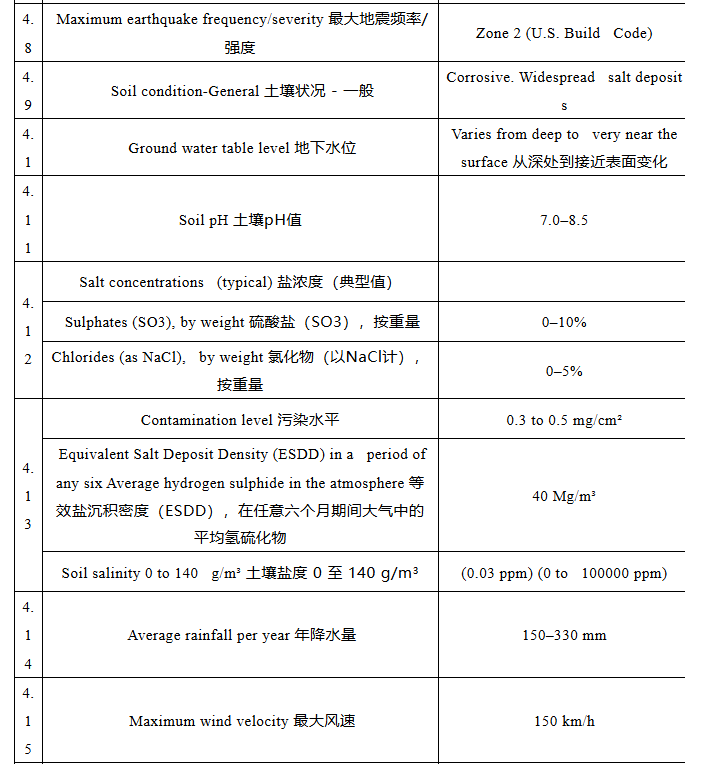

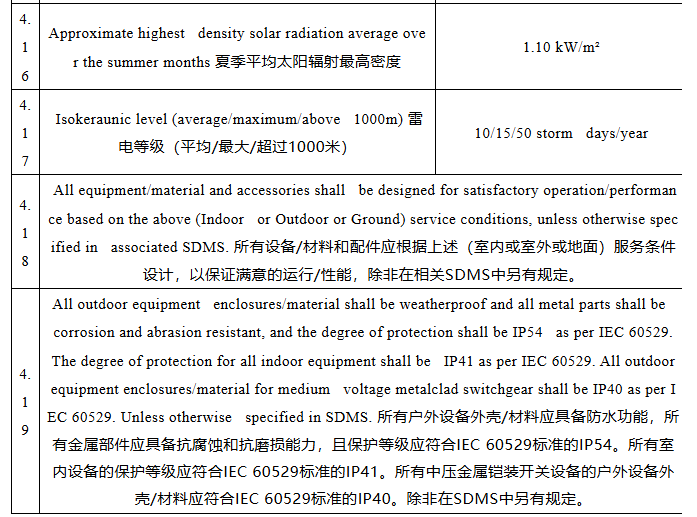

4. SERVICE CONDITIONS 服务条件

Unless otherwise specified in the associated SDMS, the equipment/material shall be suitable for operating at their standard ratings under the usual service condition in the inland, desert or coastal areas environment in the Kingdom of Saudi Arabia as follows:

除非在相关SDMS中另有规定,设备/材料应适用于在沙特阿拉伯王国的内陆、沙漠或沿海区域环境下,在其标准额定值下运行,具体条件如下:

5. PROTECTIVE COATINGS 防护涂层

Unless otherwise specified, the equipment/material shall be protected from corrosion either by hot-dip galvanizing or by a combination of galvanizing and painting (a duplex system). The duplex system, wherever required, shall be specified and described in the relevant SDMS.

除非另有规定,设备/材料应通过热浸镀锌或镀锌与涂漆结合的方式(双重系统)进行防腐。双重系统的要求应在相关SDMS中具体说明。

5.1 GALVANIZING 镀锌

Unless otherwise specified in associated SDMS or respective standard drawings, the hot dip galvanizing shall be in accordance with the following standards:

除非在相关SDMS或标准图纸中另有规定,热浸镀锌应符合以下标准:

5.1.1 ASTM A123 for Steel Structures, Steel Poles. The minimum average thickness of zinc coating shall be 0.100 mm (equivalent to 700g/m²).

5.1.1 ASTM A123 钢结构、钢柱。锌涂层的最小平均厚度应为0.100 mm(相当于700g/m²)。

5.1.2 ASTM A 153 for Hardware Fittings, Caps of Insulators and Fasteners (bolts, nuts and washers). The minimum average thickness of zinc coating shall be 0.086 mm (equivalent to 610g/m²).

5.1.2 ASTM A153 五金配件、绝缘子帽和紧固件(螺栓、螺母和垫圈)。锌涂层的最小平均厚度应为0.086 mm(相当于610g/m²)。

The minimum average thickness of zinc coating for bolts, nuts and washers shall be:

螺栓、螺母和垫圈的锌涂层最小平均厚度应为:

a. 0.053 mm (381 g/m²), for fasteners over 9.52 mm in diameter.

a. 0.053 mm(381 g/m²),用于直径大于9.52 mm的紧固件。

b. 0.043 mm (305 g/m²), for fasteners of diameter 9.52 mm and under.

b. 0.043 mm(305 g/m²),用于直径小于或等于9.52 mm的紧固件。

5.1.3 The galvanizing thickness shall be as per manufacturer's standard for all other equipment such as circuit breakers, disconnect switches, etc.

5.1.3 镀锌厚度应根据制造商标准进行,适用于其他设备,如断路器、隔离开关等。

5.2 PAINTING 涂漆

5.2.1 Painting shall be a combination of compatible paints comprising of primer, intermediate coat (on as needed basis) and top coat(s) to achieve optimum protective and decorative coating against atmospheric corrosions caused by tropical climatic conditions, wind-blown dust, sand, salt, high humidity and temperature fluctuations.

5.2.1涂漆应采用兼容的涂料组合,包括底漆、中间涂层(根据需要)和面漆,以实现最佳的保护性和装饰性涂层,防止热带气候条件、风吹尘土、沙子、盐分、高湿度和温度波动所引起的大气腐蚀。

5.2.2 For all equipment used in distribution substations or distribution networks, color shall be cement gray shade (RAL 7033) per Munsell No. 5.0 BG 7.0/0.4 or light gray shade (RAL 7035) conforming to BS 381C/2660 or ASTM D1535, respectively. Unless otherwise specified in the associated SDMS.

5.2.2对于用于配电变电站或配电网的所有设备,颜色应为水泥灰色(RAL 7033),符合Munsell No. 5.0 BG 7.0/0.4,或浅灰色(RAL 7035),符合BS 381C/2660或ASTM D1535标准,具体依据。除非在相关SDMS中另有规定。

5.2.3Manufacturer's standard painting system shall be acceptable provided that the following SEC paint performance requirements are met:

5.2.3只要满足以下SEC涂料性能要求,制造商的标准涂装系统应为可接受:

a. The paint coating shall be deemed to last the life of the equipment/material or at least ten (10) years, whichever is less.

a. 涂层应持续设备/材料的使用寿命,或至少十(10)年,以较短者为准。

b. The paint coating shall be capable of withstanding the effect of ultraviolet rays or direct solar radiation at its installed location without change in color.

b. 涂层应能耐受紫外线或直射太阳辐射的影响,在安装位置不改变颜色。

c. When a paint-coated equipment/material is tested for abrasion, there shall be no penetration through the paint coating to the substrate.

c. 当对涂漆设备/材料进行耐磨测试时,涂层不得穿透基材。

d. When a paint-coated equipment/material is tested by impact, there shall be no cracking of the paint coating nor any detachment from the substrate.

d. 当对涂漆设备/材料进行冲击测试时,涂层不得出现裂纹,也不得从基材上脱落。

e. When a painted or coated equipment/material is tested by salt spray for 1000 hours per ASTM B-117, there shall be no blistering, softening, or detachment of the paint coating. There shall be not more than 1.0 mm of corrosion creep from the scribed, equivalent to rating number 8, in accordance with Table 1 of ASTM D1654.

e. 当对涂漆或涂层设备/材料进行ASTM B-117标准盐雾测试1000小时时,涂层不得出现起泡、软化或脱落。从划痕处的腐蚀蔓延不得超过1.0 mm,相当于ASTM D1654标准表1中的等级8。

f. After the equipment/material has been washed with water and allowed to dry for 24 hours, it shall be tested for adhesion using Method B in accordance with ASTM D3359. The adhesion scale shall be 5B, wherein the edges of the cuts are completely smooth and none of the square of the lattice is detached, unless within 1.0mm of the scribed.

f. 当设备/材料用水清洗并晾干24小时后,应根据ASTM D3359标准使用方法B进行附着力测试。附着力等级应为5B,切口的边缘应完全平滑,且网格的方格没有脱落,除非在划痕范围1.0mm内。

g. When a paint-coated equipment/material is tested for its resistance to humidity, there shall be no blistering, softening, or detachment of the coating nor signs of corrosion of the equipment/material.

g. 当涂漆设备/材料测试其抗湿性能时,涂层不得出现起泡、软化或脱落,也不得出现设备/材料的腐蚀迹象。

5.3 DUPLEX SYSTEM 双重保护系统

5.3.1 Duplex system of protection of equipment/material from corrosion shall be a combination of hot dip galvanizing and painting. This system of corrosion protection may be used by the manufacturer in areas falling within 50 km from the sea coast, with prior approval from SEC.

5.3.1设备/材料的防腐保护双重系统应由热浸镀锌和涂漆组合而成。该防腐保护系统可以由制造商在距离海岸线50公里范围内使用,但需事先获得SEC的批准。

5.3.2 The duplex system shall be deemed to have a life at least 30 years or more.

5.3.2双重保护系统的使用寿命应至少为30年或更长。

5.3.3 The paint system shall comprise of one primer coat, intermediate coat(s), and top (finish) coat(s). The thickness of zinc coating shall be a standard thickness as per ASTM 123 whereas the thickness of paint shall be as per manufacturer's recommendations and subject to approval by SEC.

5.3.3涂漆系统应包括一个底漆层、中间涂层和面漆层。锌涂层的厚度应符合ASTM 123的标准厚度,而涂层的厚度应根据制造商的推荐,并须获得SEC的批准。

5.3.4 In case the contractor adopts this system, complete details of the paint system and procedures for application shall be submitted for review and approval by SEC.

5.3.4如果承包商采用此系统,应提交涂漆系统的完整细节及应用程序供SEC审查和批准。

5.4 ALUZINC STEEL 铝锌钢

Aluzinc cold rolled galvanized steel with metal coating composed of Aluminum (55%), Zinc (43.4%) and silicon (1.6%) will be acceptable for the application which mainly depends on steel sheets such as LVDP, Cabinets, Enclosures.

冷轧镀铝锌钢,金属涂层由铝(55%)、锌(43.4%)和硅(1.6%)组成,将被接受用于主要依赖钢板的应用,如LVDP、机柜、外壳。

5.5 UNDERGROUND MATERIALS 地下材料

Unless otherwise specified, the manufacturer/vendor shall propose appropriate corrosion protection measures, other than specified above, for the application of material for underground installation for SEC review and acceptance.

除非另有规定,制造商/供应商应提出适当的防腐保护措施,作为地下安装材料的应用,以供SEC审查和接受。

6. INSPECTION AND TESTING 检验与测试

6.1 SEC reserves the right to inspect the equipment/material at the factory, as SEC deems necessary, for compliance with the terms and conditions of the Purchase Order to witness any or all the tests required by the aforementioned documents and the associated SDMS.

6.1 SEC有权根据需要,在工厂对设备/材料进行检查,以确保符合采购订单的条款和条件,并见证所有或部分所需的测试,测试要求来自上述文件和相关的SDMS。

6.2 SEC may require certificates and data from the manufacturer/supplier on all pertinent aspects of the manufacturing process.

6.2 SEC可能要求制造商/供应商提供有关制造过程所有相关方面的证书和数据。

6.3 In order to permit SEC or its designated representative to be present for inspection and tests, the manufacturer/vendor shall give a minimum of 30 days for local inspection visits and 60 days for abroad inspection visits advance notice of his intention to carry out tests on equipment/material being made available for inspection. In the case of tests of long duration, the actual date of commencement shall be mutually agreed between the manufacturer/vendor and SEC or its designated representative.

6.3为了允许SEC或其指定代表参加检查和测试,制造商/供应商应提前至少30天(本地检查访问)和60天(国外检查访问)通知其进行设备/材料检查的意图。如果测试需要较长时间,开始日期应由制造商/供应商与SEC或其指定代表共同商定。

6.4 No equipment/material shall be delivered to the Company until the manufacturer receives a "Release for Shipment Certificate" from SEC or its designated representative. Release for shipment certificate is required prior to dispatch of any equipment/material even if SEC or its designated representative does not perform inspection or surveillance activity at the manufacturer's facility.

6.4在制造商收到来自SEC或其指定代表的“发货许可证”之前,任何设备/材料不得交付给公司。即使SEC或其指定代表没有在制造商设施进行检查或监督活动,发货许可证仍然是发运任何设备/材料之前的必要文件。

6.5 Issuance of the Release for Shipment Certificate shall not be construed as waiving any of SEC rights to carry out receipt inspection at SEC receiving facilities and rejection of the equipment/material if not complying with the Purchase Order and the Specifications.

6.5发货许可证的签发不应被视为放弃SEC在接收设施进行收货检查的权利,如果设备/材料不符合采购订单和规范,SEC有权拒收。

6.6Vendor/manufacturer shall submit Quality Control Plan/Inspection and Test Plan (QCP/I&TP) of the proposed equipment/material per Contract Schedules or three (3) to four (4) weeks after receipt of the Purchase Order and prior to commencement of the manufacturing for review and approval by SEC. This shall be in line with GI 05.

6.6供应商/制造商应根据合同进度表提交拟议设备/材料的质量控制计划/检验和测试计划(QCP/I&TP),提交时间应为收到采购订单后的三(3)至四(4)周,并在制造开始前提交供SEC审查和批准。此计划应符合GI 05。

6.7 The Quality Control Plan shall list and define in sequential order all process control activities, inspection and tests (design, routine and special) required and proposed to be performed on the equipment/material starting from component procurement, as and testing stages to product dispatch. The Quality Control Plan shall indicate and identify the applicable standard, detailed description with diagram of the procedure, acceptance criteria, extent check and record to be generated, reviewed and retained.

6.7质量控制计划应按顺序列出并定义所有过程控制活动、检验和测试(设计、常规和特殊),要求并建议在设备/材料的各个阶段(从组件采购、测试阶段到产品发货)执行。质量控制计划应注明适用的标准、程序的详细描述(附图)、验收标准、检查范围和需要生成、审查和保留的记录。

6.8 SEC reserves the right to require from the manufacturer/supplier performing new type test at approved laboratory with the witness of SEC representatives every five (5) years and/or if any modification is done on the approved equipment/materials.

6.8 SEC有权要求制造商/供应商每五(5)年在批准的实验室进行新型测试,并由SEC代表见证;如果对批准的设备/材料进行了任何修改,也应进行测试。

6.9 SEC reserves the right to require from the manufacturer/supplier performing training courses and/or events for SEC employees during the guarantee period free of charge.

6.9 SEC有权要求制造商/供应商在保修期内为SEC员工提供免费培训课程和/或活动。

7. PACKING AND SHIPPING 包装与运输

7.1 All equipment/material shall be delivered within a stipulated period as per the contract.

7.1所有设备/材料应在合同规定的期限内交付。

7.2 Export packing and shipping shall be adequate for sea transport and handling up to site in Saudi Arabia.

7.2出口包装和运输应适合海运,并能够处理直到沙特阿拉伯现场的运输。

7.3 Each assembly or component shall be skidded, crated, boxed or otherwise suitably protected against damage or loss during shipment and to facilitate field hand storage. All openings shall be effectively sealed with temporary closures to prevent entry of dust, dirt, moisture and other foreign matter.

7.3每个组件或部件应放置在托盘、木箱或其他适当的包装中,以防在运输过程中损坏或丢失,并便于现场储存。所有开口应通过临时封闭物有效封闭,以防止灰尘、污垢、湿气和其他杂物进入。

7.4 Each crate or container shall be marked with the number of pieces contained therein, the manufacturer's catalog number and description of the content, the manufacturer's name, the SEC Item Number, the SEC Purchase Order Number, Contract No. or J.O. No. and the gross weight in kg, as applicable.

7.4每个木箱或容器应标明其中包含的件数、制造商目录编号和内容描述、制造商名称、SEC物品编号、SEC采购订单编号、合同编号或J.O.编号,以及毛重(以公斤为单位),如适用。

7.5Additional handling and shipping instructions shall be obtained from SEC Materials Management Department, or other departments, as applicable.

7.5额外的处理和运输指示应从SEC物资管理部门或其他相关部门获取。

7.6 All equipment/materials prequalified by SEC to be used at SEC properties and having SEC logo are exclusive use only for SEC company and shall not be sold to the local market.

7.6所有经过SEC预审的、用于SEC资产且带有SEC标志的设备/材料仅限于SEC公司专用,不得出售给本地市场。

8. DOCUMENTATION REQUIREMENTS 文件要求

8.1 GENERAL 一般要求

8.1.1 English language shall be used at all times with respect to documents, drawings, and labels procured or prepared by the manufacturer/vendor pertaining to the work.

8.1.1所有与工作相关的文件、图纸和标签,无论是由制造商/供应商采购还是准备,都应始终使用英语。

8.1.2 All dimensions shall be in SI units.

8.1.2所有尺寸应使用国际单位制(SI单位)。

8.2 DOCUMENTATION 文件资料

8.2.1 The manufacturer/vendor shall provide the specific parts full data and documentation as specified in SEC Quotation Request Package (instructions to vendors) and Non-Material Requirements (e.g., drawings for approval, certified drawings and operating manuals) attached to the Quotation Request and subsequently to the Purchase Order.

8.2.1制造商/供应商应提供SEC报价请求包(供应商说明)和非物资要求(例如,供审批的图纸、认证图纸和操作手册)中规定的具体部件的完整数据和文件,并附于报价请求及随后提交采购订单。

8.2.2 The manufacturer/vendor shall submit two (2) copies of the quotation along with Data Schedule duly filled in and two (2) sets of outline drawings of the equipment/material showing dimensions, assembly and mounting details for SEC's evaluation and acceptance.

8.2.2制造商/供应商应提交两(2)份报价单,并附上完整填写的数据时间表,以及两(2)套设备/材料的轮廓图,显示尺寸、组装和安装细节,供SEC评估和接受。

Technical literature, catalogs, and certified Type Test reports conducted at Independent Test Laboratories or witnessed by SEC approved QA/QC Services Contractors, for the proposed or identical equipment/material shall also be submitted for SEC's evaluation and acceptance.

技术文献、目录以及在独立测试实验室进行或由SEC批准的QA/QC服务承包商见证的认证型式测试报告,针对拟议或相同设备/材料,也应提交给SEC进行评估和接受。

9. GUARANTEE 保证

The vendor/manufacturer shall give a general guarantee against all defects arising out of faulty design or workmanship or defective material for a period of five (5) years from the date of delivery. Special or additional guarantee will be mentioned in the relative material specification/description.

供应商/制造商应提供一般保证,针对因设计缺陷、工艺缺陷或材料缺陷引起的所有缺陷,保修期为交货日起五(5)年。特别的或额外的保证将在相关材料规范/描述中注明。

10. EXCEPTION AND DEVIATIONS 例外与偏差

10.1 The manufacturer/vendor shall furnish a clause-by-clause compliance of this Specification and the associated SDMSs clearly indicating the provisions/features of the tendered equipment/material.

10.1制造商/供应商应提供逐条符合本规范和相关SDMS的声明,明确指出投标设备/材料的条款/特点。

10.2 The manufacturer/vendor shall clearly state and give a list of deviations or exceptions. Every exception/deviation shall indicate:

10.2制造商/供应商应明确说明并列出所有偏差或例外。每个偏差/例外应注明:

10.2.1Applicable clause/section of this Specification and/or the associated SDMS, as applicable.

10.2.1本规范和/或相关SDMS中适用的条款/章节,视情况而定。

10.2.2 Reasons for the exceptions/deviations.

10.2.2例外/偏差的原因。

10.3 SEC reserves the right to reject any or all of the exceptions/deviations without assigning the reasons.

10.3 SEC保留拒绝任何或所有例外/偏差的权利,无需说明理由。

译者:Cara de Daniel 转自公众号- 电力市场洞察

免责声明:翻译过程中借助了AI,由于AI幻觉,错误在所难免,本人不对翻译的错误导致的损失负责,有业务上的需求,请研究官方的英文文档,切勿依赖本文档的中文翻译。