> Digital transformation is key to updating and improving manufacturing operations and helping them be more automated and efficient.

BY VICTOR BERTORELLI FROM CONTROL ENGINEERING

What is digital transformation and how can it help my company?

Digital transformation refers to the leveraging of digital technologies to transform and innovate business processes. Newly-developed digital technologies offer many opportunities for businesses to improve efficiency, cut costs, or save time, making digital transformation a key factor for businesses adapting to a fast-changing market.

For process manufacturing, digital transformation—the base of “Industry Manufacturing 4.0”—is also key to updating and improving operations. Many chemical companies, food and beverage manufacturers, and pharmaceutical companies (amongst others) are still struggling with production systems that are obsolete. In most cases, these systems require multiple points of manual intervention throughout the production process, increasing the odds of human error and potentially decreasing the consistency of product. With digital transformation, however, your company can introduce an automated process that can improve your flexibility and consistency while also reducing costs and hassle.

The benefits of the digital recipe

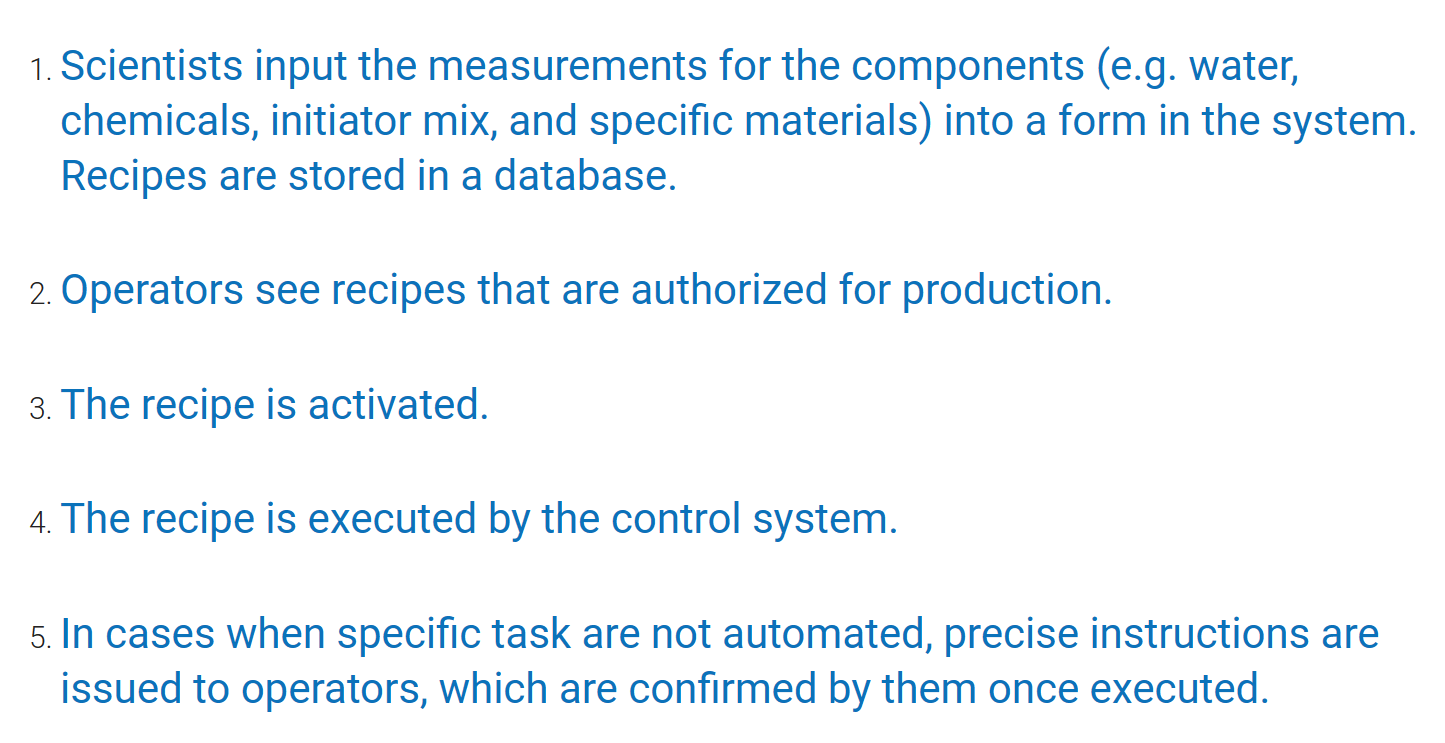

Introducing an automated digital process can reduce training costs, decrease the potential for human error, offer more flexibility, and maintain consistency in operations and results. For the scientists mentioned above, for example, we used PlantPAx (Rockwell Automation’s Plant Wide Control System) as our base platform and implemented a Product Configuration application to manage the scientists’ requirements. In this case, the process went something like this:

In this scenario, the computerized system guides each step of the process and guarantees all parts of the production system are prepared for the next step in the process. Few operator trainings are needed, and the automation of the system reduces the possibility of human error affecting the process (and, therefore, the final product). In addition, the scientists are much more flexible with the changes they can make and how often they can make them while keeping the process and product consistent.