Ioana Macaneata from Adapta Robotics

ERIS, the semi-autonomous retail robot

This article taps into discussing problems met by retailers and ways in which they can be solved with robotic automation.

Artificial Intelligence

- Automation

- Labelling

- Robotics

The Causes of Ongoing Problems for the Retailers

A store’s success depends on customer satisfaction and convenience while alleviating staff’s frustration with repetitive, monotonous tasks. Retailers see in-store inventory and price management in need of optimization and improvement to deliver the convenience customers are asking for.

Sources of the Retailers’ Price Accuracy Issues

Taking into consideration that consumer-packaged goods (and especially retail) prices tend to change frequently, labels displayed in-store need to adapt as fast as the modifications happen. Failure to present accurate pricing and promotions inconveniences customers’ buying journey. In correlation, shopping experiences poisoned by the inconvenience of inaccurate labeling lead to loss of business, which is never desired.

Retailers have the responsibility to monitor if products are precisely named, marked with the correct price or if the right promotions are applied. Each label must be verified against the store’s price and promotions database. Such processes are defined by repetition and monotony, heavily relying on staff, an excessive amount of time to be finalized, and continuous implementation.

Sources of the Retailers’ Inventory Issues

Stock and inventory management goes beyond a retail store’s backroom and extends in front of the customers, on shelves. It is a multi-level process defined by a long communication chain that is prone to errors and delays. More than ordering and restocking, issues of the supply operations target trends and patterns, data collection, demand forecasting (dependent on store data), on shelf stock condition monitoring (misplacement, clutter, missing).

Having overviewed the price and inventory issues retailers confront, let’s explore existing solutions for their correction.

In-store on-shelf availability and price labels

Solutions Available to Retailers

Solutions that solve problems of the supply chain are starting to get to the heart of the retailer. Even though they approach shelf gap detection and in-store inventory data, monitoring on-shelf availability needs a more robust solution that tackles these issues holistically.

The retail automation market is extensive, and there are three solutions that seem to be under retailers’ consideration more often than the others.

Electronic Shelf Labels and Shelf Cameras

Autonomous robots

Semi-Autonomous robots

Technologies such as Electronic Shelf Labels, to maintain price accuracy, and retail shelf-mounted cameras, to track product availability, are currently being deployed to physical stores to boost operational efficiency.

Electronic Shelf Labels (ESL) as a Solution for In-Store Price Inconsistencies

Electronic Shelf Labels are small units using e-Ink paper to display product data from price and name to stock availability or applied promotions. Being updated wirelessly and automatically from systems that centralize product information, ESLs serve retail operations concerning on-shelf price conformity.

To populate a supermarket-sized perimeter with smart labels, a retailer must invest in thousands of individual shelf-placed units. However, ESLs have replaced repetitive tasks with others of the same nature. Labels are not scanned by hand, but that doesn’t prevent malfunctions of the electronic price tags. The printing and individual placement of paper tags is changed with a tedious battery or device replacement process, slowed down by difficult installation operations and expensive infrastructure costs. Additionally, as the store integration process of ESLs is highly dependent on the company they’ve been acquired from, so is the maintenance process.

On-shelf availability (OSA) refers to the products available to be purchased from a store, by customers at a given time. To monitor levels across the supply chain, retailers have slowly moved from manual audits to solutions based on artificial intelligence and computer vision. One of those solutions is retail cameras for on-shelf availability.

ESLs-Electronic price labels

Shelf Camera Features for Monitoring In-Store Inventory / OSA

From an operational point of view, shelf cameras do an excellent job when it comes to product and stock detection, compliance with product placement strategies, and data collection (inventory updates, shopping patterns). However, with shelf gaps being only one side of the problem, the retail shelf cameras build to high expenses and reliance on long communication chains prone to human error. Passive monitoring of OSA does not refill shelves, solve labels’ accuracy issues or their replacement.

Maintenance processes and costs for hundreds of devices do not justify the need for total, constant surveillance of products. The surge in product demand remains unpredictable and concentrated under the peak traffic periods of the shopping day or promotional campaigns.

Retail OSA cameras not only require installation procedures that are lengthy and costly but also depend on the manufacturer across maintenance processes. From cables and mounting supports to network administration, and overall system setup and integration with the retail store, shelf cameras introduce supplementary tasks for which the staff needs to be rigorously trained.

Having its focus only on-shelf availability and out-of-stock situations, shelf cameras are a solution that although popular still struggles to have their cost versus benefits validated by retailers. Complex integration processes and long adjustment timeframes for retailers and staff to operate the new system contribute to the impeded adoption growth of OSA cameras. Retailers must be ready for a considerable commitment upfront and ongoing, as they are indirectly forced into vendor lock (training, store integration, updates, and maintenance are dependent on the manufacturer of the solution). They need to be prepared for changes brought to the store’s infrastructure, already implemented software and solutions, and a different way of operation and specialized workforce demand.

Shelf camera view

ESLs and shelf cameras are solutions dependent on human intervention, relying on interventions subsequent to the reported data. Hence, development in retail automation has taken a giant leap toward solutions that aim to function without the need for human help.

Covering both price and inventory issues, autonomous robots have brought a new level of efficiency to in-store tasks as well as new problems and complexities that retailers have not been prepared for.

The Complicated Transition to Autonomous Retail Robots

Autonomous robots are used and are known for scanning a store for price tag inconsistencies, on-shelf inventory, and stock issues. Although bringing efficiency to OSA and price tag detection-related tasks, in-store problems are still not solved in their integrity (communication chains are still long and error-prone). Issues are detected and signaled but to actually replace a price label or replenish on-shelf stocks are actions still dependent on long, error-prone communication chains.

The solution has been put into question, its utilization causing trouble in retail stores and not delivering the expected results. Consumers have had trouble adapting to the self-roaming robot attacking, getting scarred by or being hurt by its ROI issues, high acquisition and maintenance costs, together with the registered malfunctions, make retailers question fully autonomous solutions.

Building bridges between solutions that are outdated, incomplete, and heavily reliant on staff intervention (ESLs and shelf cameras) and the farfetched, costly autonomous robots, semi-autonomous robots are collaborating with humans to deliver the best of both worlds.

A Semi-Autonomous Robot Solves Multiple Problems

With a semi-autonomous robot, the workforce required to execute tedious retail operation tasks is reduced to one staff member who oversees guiding the robot along the aisles and reviewing the output results of scanning sessions. The same operator can take action to resolve or communicate in-store pricing mistakes or out-of-stock issues.

Most problems found during scanning can be resolved immediately, reducing the danger of misinformation or action delays by reducing the need for interdepartmental contact. Being semi-autonomous not only offers the advantage of being user-friendly (no specialized staff needed) but also more cost-effective than other solutions. The thing it needs most is to be brought from the charging station to the designated scanning start point.

Introducing ERIS, the Semi-Autonomous Retail Robot

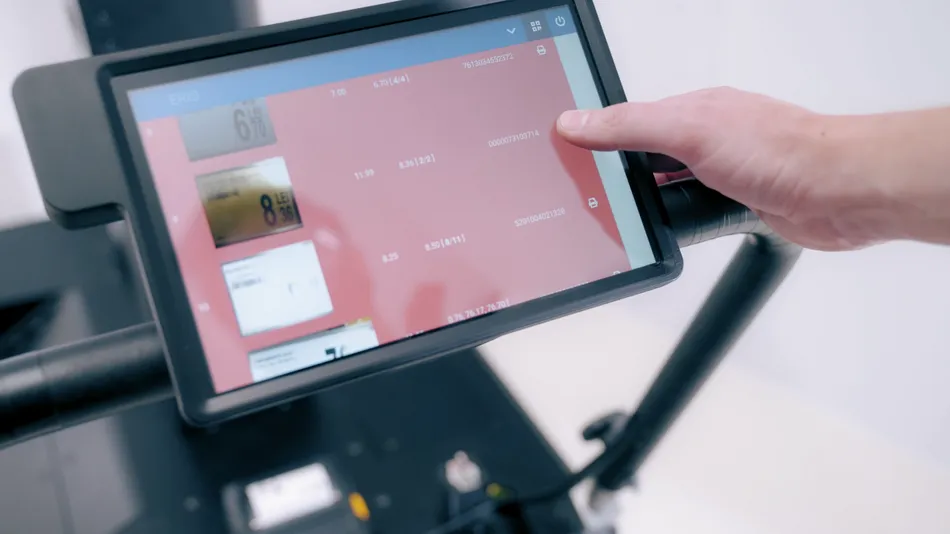

ERIS- on-the-spot label printing and replacement

ERIS completes the functionalities of shelf cameras through additional capabilities and uses cases that treat OSA issues globally not partially. By being able to detect and scan both paper labels and e-ink electronic tags, the semi-autonomous robot makes the task of monitoring labels, including ESLs malfunctions, easier. As the shelves are scanned, when price tag issues are detected, the operator can print the correct labels and replace them on the spot or send alerts about the electronic tags that need to be updated.

Takeaways

In-store pricing accuracy and on-shelf inventory issues are on top of retailers' minds when it comes to delivering convenience and satisfaction to customers. ESLs, shelf cameras, and autonomous robots have been overviewed as some of the most popular solutions considered by retailers. However, they have their own shortcomings when comparing the delivered results to the overall investment.

Putting it into perspective, the semi-autonomous robot eliminates risks and concerns brought by its fully autonomous competitors while being a more complete solution than electronic shelf labels and shelf cameras. Human-operated robots like ERIS not only does it sponsor a better ROI, but it is also easy to integrate, maintain and get accustomed to solutions.