Tess Boissonneault

Everything you need to know about fixed automation, programmable automation, flexible automation, and integrated automation.

When we talk about automation, there is a tendency to picture cutting-edge technologies, like self-driving cars and sophisticated robots. But automation has existed in some form or another for centuries and many automated technologies are now quite commonplace. The primary history of automation dates back to the Industrial Revolution, though we can trace roots back even further. Water mills used to mill grain have existed since the time of Ancient Greece; windmills have existed since the 12th century.

In the Industrial Revolution, however, automation really took hold with a slew of new manufacturing technologies that were invented to reduce the reliance on human labor. Devices like conveyor belts, mechanized looms, steam engines, and more led to the proliferation of factories that could produce products on a mass scale like never before. Electrification in the early 1900s and advances in signal processing throughout the early and mid 20th century led to further automation and revolutionized every aspect of society, from communication to manufacturing.

Today, it is not quite as simple as talking about “automation”, because the term can mean a lot of things. Industrial automation can look like a conveyor belt moving products along an assembly line; it can look like a CNC machine milling a part from a metal blank; it can look like a robotic arm manipulating objects; and it can look like an entire lights-out factory working independent of any human intervention. Because of this versatility, it is helpful to categorize the different types of automation.

Technician in automated factory

Automation is a versatile topic. In industrial manufacturing, there are four main types of automation.

Four Types of Industrial Automation Systems

Within the context of industrial applications for automated processes, there are four key types of automation: fixed automation, programmable automation, flexible automation, and integrated automation. Let’s take a look at what each kind of automation is.

Fixed Automation

Fixed automation, also known as hard automation, refers to a manufacturing technology that is engineered to automate a specific task. Fixed automation solutions are typically simple and are built for one purpose, like assembling a specific part or material handling. Fixed automation systems are highly efficient and are ideal for achieving fixed, repetitive production steps in mass-scale production lines.

An automated conveyor belt is an example of fixed automation: the system operates independently throughout the manufacturing process and its purpose is to carry products along an assembly line. Other common forms of fixed automation are automated assembly machines, which are programmed to assemble specific parts, or automated painting processes designed to coat a specific product with a finishing paint or sealant.

Unlike some of the other types of automation we will explore below, fixed automation systems have an internal programming. In other words, it is their hardware that controls them, rather than software. This makes it challenging to adopt fixed automation systems for different types of products or to accommodate product changes. Instead, fixed automation is best fit for mass producing a single type of product or part assembly. Fixed automation solutions are widespread in industrial production: these systems add value by driving production rates and efficiency and decreasing labor costs.[1]

Programmable Automation

The next type of industrial automation is programmable automation. This subcategory of automation equipment is characterized by its ability to carry out the same task but in different ways. For example, while fixed automation might only be capable of moving from A to B, a programmable automation technology could be programmed to move from A to B, and then subsequently be programmed to move from A to C.

Programmable automation solutions are most commonly used for batch production: the equipment is programmed to fulfill a specific task, which it repeats over the course of a single batch. It can then be programmed again to accommodate changes required for a new batch. Examples of programmable automation are CNC machines, which receive instructions from a computer program, industrial robots, whose motions and actions can be programmed, and steel rolling mills, which can be programmed to produce different thicknesses of metal.

This type of automation is best suited to batches of up to several thousand parts rather than one-off production because reprogramming the equipment takes time. This means that any changeover between product varieties will necessitate machine down time, which slows down production rates.[2]

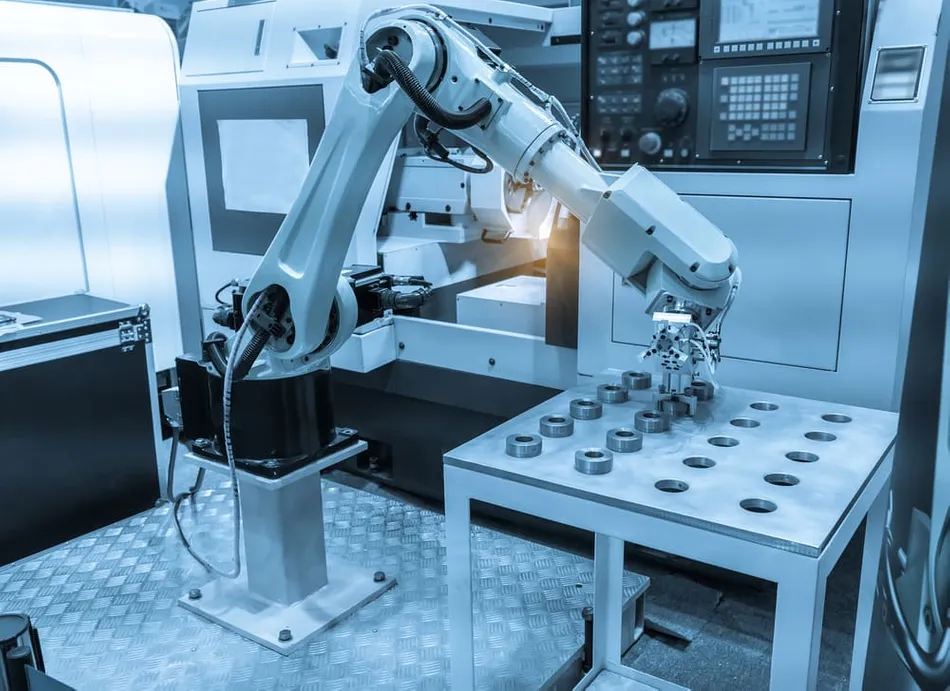

Robotic arm

Robotic arms are key to unlocking integrated automation on the factory floor.

Flexible Automation

Flexible automation, sometimes called soft automation, refers to manufacturing equipment that is controlled by a computer program and is capable of carrying out a diversity of tasks based on the code it has been fed. Unlike programmable automation, which can be programmed for different products but requires significant down-time to do so, flexible automation solutions can be adapted rapidly and often automatically. In most cases, flexible automation only requires software changes (i.e. via a remote computer) rather than hardware changes, minimizing machine downtime and facilitating product changeovers.

With flexible automation, it is possible to produce parts in batches or to manipulate different types of parts in succession. For example, a 6-axis robotic arm can be programmed to carry out a range of tasks in a production line, including drilling holes, joining components, and more. It could also be programmed to do something completely different the following day or week if needed. An industrial 3D printer could also be used to fulfill flexible automation: technicians can easily change printer settings and send a different CAD file to start producing a new design.

The primary advantage of flexible automation is that it enables high-mix production and flexible manufacturing workflows, easily accommodating changes to product designs as well as a variety of products. One of the current challenges to the broader adoption of flexible automation solutions, however, is its high cost barrier: robotic arms and other flexible automation equipment require a significant upfront investment.

Integrated Automation

Integrated automation refers to an end-to-end automated manufacturing process that does not require any human intervention. In an integrated automation workflow, a computer software system controls and connects the various pieces of manufacturing equipment on the production floor. Once settings and parameters have been set by an engineer or technician, the integrated automation solution carries out the instructions independently and can respond if any inconsistencies occur thanks to artificial intelligence and machine learning technologies.

While the aforementioned types of automation describe specific systems or pieces of equipment, it is perhaps more helpful to think of integrated automation as a sort of framework. It underpins various automated hardware and connects each step in a production chain, resulting in a single, cohesive process rather than multiple distinct steps.

Lights-out manufacturing is an example of integrated automation in action. It refers to when a manufacturing facility can operate without any human involvement and even supervision. Robots and automated equipment are responsible for every step in the process, as well as material and part handling. Today, many manufacturers are aiming to achieve lights-out production to increase productivity, achieve high production rates, and minimize the reliance on skilled human operators—of which there is often a shortage.

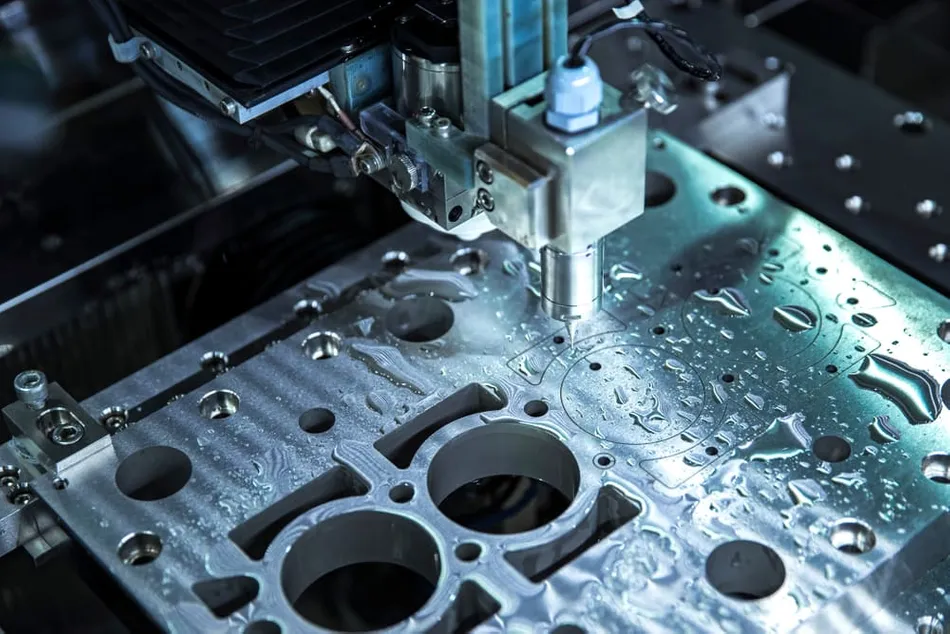

CNC machining close-up

Lights-out manufacturing is a fully automated production line that requires no human intervention or supervision.

Advantages and Disadvantages of Automation

Automation is a key part of what is heralded as “Industry 4.0”, or the Fourth Industrial Revolution. Through a combination of smart machines, control systems, and automation tools, manufacturing operations are able to function more independently, with various steps in the process communicating with each other and process data informing computer system decisions in real-time.[3]

Whenever we talk about a new manufacturing or industrial framework, there are two sides to the story. Automation, particularly integrated automation, represents a massive paradigm shift in manufacturing that has many people feeling very optimistic and many feeling quite anxious. It’s important to look at both sides to understand where the benefits and disadvantages lie, and how to address them.

Advantages:

Productivity: One of the main reasons that manufacturers are investing increasingly in automation is because it can unlock higher productivity rates. With automation, tasks throughout the production chain—or the chain as a whole—can operate independently and with greater efficiency.

Consistency: With automated technologies in place, manufacturers can benefit from greater process consistency thanks to in-depth process monitoring data. A lower reliance on human labor also minimizes the risk of human error in the production process.

Labor: This is admittedly a tricky one (you’ll also find it in the disadvantages section). There are benefits for both employers and employees when it comes to industrial automation. For one, automation enables manufacturers to mitigate the effects of labor shortages, particularly for skilled technicians. They can keep up production rates and even scale without having to seek out and hire additional workers. For another, automation eliminates the need for humans to undertake many tedious, repetitive tasks. This creates more space for more complex and valuable tasks that require problem solving, such as product development, process supervision, and big-picture strategizing.

Disadvantages:

Cost: While there are long-term cost benefits for integrating automation in production workflows, the transition to automation and Industry 4.0 comes with a significant initial cost due to the high price of automated equipment and software tools. This cost can be prohibitive to smaller producers, and may only be viable for large manufacturing companies.

Labor: On this side of things, automation threatens existing labor forces and can lead to worker displacement. If a whole segment of jobs is suddenly automated, those workers are at risk of losing their employment and their skills may be devalued. Upskilling and trainings are an important strategy for mitigating this effect. They equip workers for new roles and give them new skills that are in demand.

Cybersecurity: As processes across manufacturing become more connected, they become more efficient but they also increase their vulnerability to cyber attacks. Malware, ransomware, and data breaches can compromise business processes significantly and come with a high cost. Establishing a robust cybersecurity system can help to minimize these risks and keep IP and production chains safe as automation is implemented.[4]

Recommended reading: Is Your Manufacturing Plant Ready for Automation?

Automation Applications in Manufacturing

In the context of industrial manufacturing, there are countless applications for automation. Many of the steps involved in transforming raw material into a finished product can be automated, including CNC milling, CNC turning, sheet rolling, stamping, pressworking, laser cutting, additive manufacturing, welding, product handling, material handling, part inspection, picking, packaging, and more.

Automated material handling, assembly machines, and other automated manufacturing systems are indispensable tools within major manufacturing facilities today, including in the automotive, food packaging, electronics, pharmaceutical, and consumer goods industries, among others.

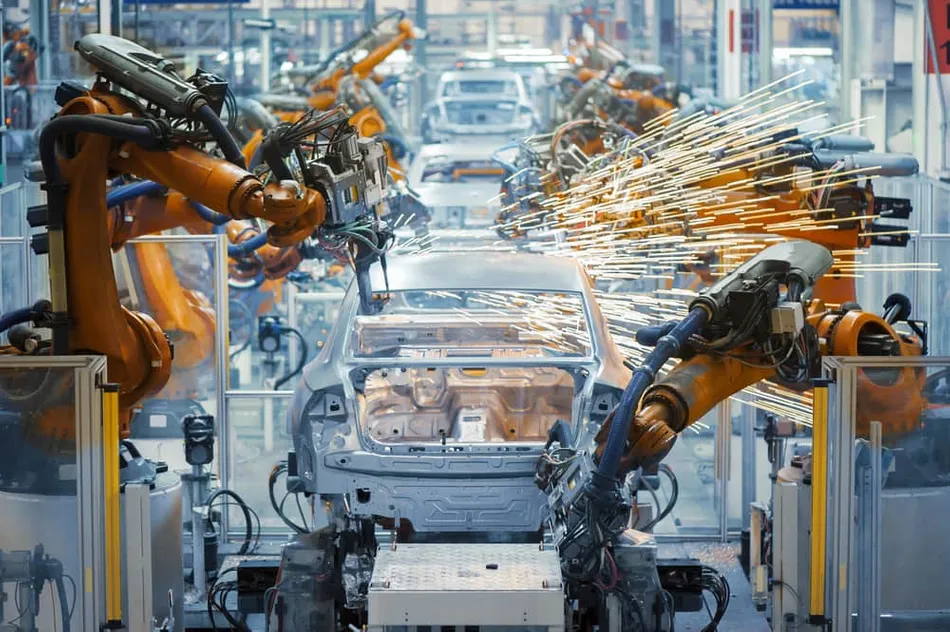

car factory with robots

The automotive industry is among those driving the adoption of industrial automation.

Key Takeaways

At its core, automation is about improving productivity and reducing the need for human labor. And it has been evolving for millenia. Thousands of years ago, water and wind mills freed people up from the labor intensive and time-consuming task of hand pounding wheat and grain. Today, the most advanced automated solutions are enabling entire production chains to go ahead without supervision. We covered a lot about automation in this article, if you’re looking for a quick summary, here it is:

There are four key types of automation: fixed automation, programmable automation, flexible automation, and integrated automation.

Fixed automation is a type of automation that is designed to fulfill a specific task and that one task only. For example, an automated conveyor belt has only one function, which it performs efficiently.

Programmable automation is a type of automation that can be reprogrammed to fulfill different variations on the same task. For example, a CNC machine can be reprogrammed to mill various different designs. Programmable automation is ideal for batch automation and requires hardware and software changes.

Flexible automation is a type of automation that is controlled by a computer program and can carry out a diversity of tasks based on the code it has been fed. Programmable automation often does not require machine down-time.

Integrated automation is an end-to-end automated manufacturing process that does not require any human intervention and is underpinned by a control system.

The main advantages of automation are higher productivity and output consistency.

The main disadvantages of automation are high initial cost and worker displacement.

Labor is a two-sided issue when it comes to automation: on the one hand, employers can mitigate labor shortages and workers are relieved from tedious, repetitive work. On the other hand, automation can replace jobs and lead to layoffs and short term unemployment issues.